Angular Plasticity¶

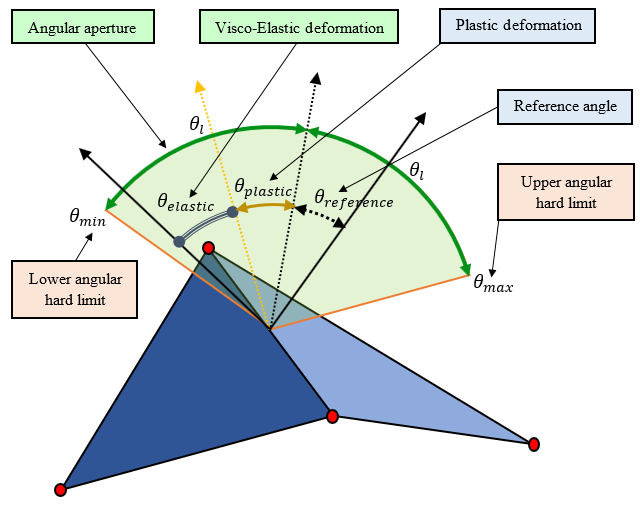

The crease primitive constrains four nodes of a cloth and rules the angular deformations around an edge shared by two faces. The reference angle is calculated between the normals of the two faces in the cloth reference pose unless using a flat angle model. The bend limit describes the aperture of the angular cone around the reference angle. Plastic and elasto-plastic deformations can only occur within this cone. Setting a bend limit of zero results in a rigid crease constraint preventing all angular deformations, making stiffness, viscosity, yield and plasticity settings ineffectual. Plastic deformation is controlled by a yield and a plasticity. The yield describes the limit in angle of elastic recovery. So, when the deformation angle is greater than the yield angle then plastic deformation is triggered. The plasticity describes how much of the current angular deformation becomes plastic. For example: if after simulation the crease has a 45 degrees deformation with a yield set to 10 degrees and a plasticity of 80 percent, then plastic deformation would be triggered (because the deformation angle 45 degrees is greater than the yield of 10 degrees) and the plastic angular deformation would be of 36 degrees (80 percent of 45 degrees). The visco-elastic deformation is produced by a spring model with stiffness and viscosity parameters. The spring applies forces to maintain the crease reference angle in absence of plasticity and it plastically deforms the reference angle when plasticity is active.