Stiffness/Viscosity¶

The stiffness and viscosity are used in two different ways: Segment Stiffness/Viscosity and Bend Limit, Stiffness/Viscosity.

Segment Stiffness/Viscosity¶

The elastic behavior of a segment, within the range limited by Compression/Extension, is modelled through a simple spring damping equation with a stiffness and a viscosity term.

Stiffness is a coefficient that is decoupled from viscosity. This means that the effect of stiffness is not diminished by the viscosity.

The viscosity is a viscous ratio and has no dimension. The choice of viscous behavior is made easy by the use of this ratio.

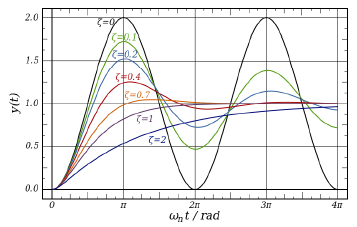

For a single segment, a viscous ratio of 0 will produce harmonic oscillations. A viscous ratio below 1 will produce under-damped pseudo periodic oscillations. A value of 1 will produce a critical damping. And finally, any value above 1 will produce over damped behaviors.

Graph from Wikipedia that illustrates the behavior of a single segment for various viscous ratios.

Note

This is the suggested method to setup segment parameters in order to achieve a given stretch behavior:

- First deactivate the compression and extension ratio in order to see the effect of visco-elasticity.

- Then set damping to 0 and find the stiffness that keeps the cloth as stiff as required (too strong stiffness will produce the same result as the compression and extension constraints set to 1).

- Setting the viscosity is then dictated by the behaviors described in Figure 5 (over damped values between 4 and 10 are very effective).

- Now reactivate the compression and extension hard limits to enforce the maximum compressibility and extensibility of the cloth.

Remember that the equilibrium can also be tuned to shrink the cloth segments towards a fraction of their reference length, allowing for interesting fiber behaviors.

Bend Limit, Stiffness/Viscosity¶

The crease primitive constrains the angle between two faces and thus involves four cloth nodes.

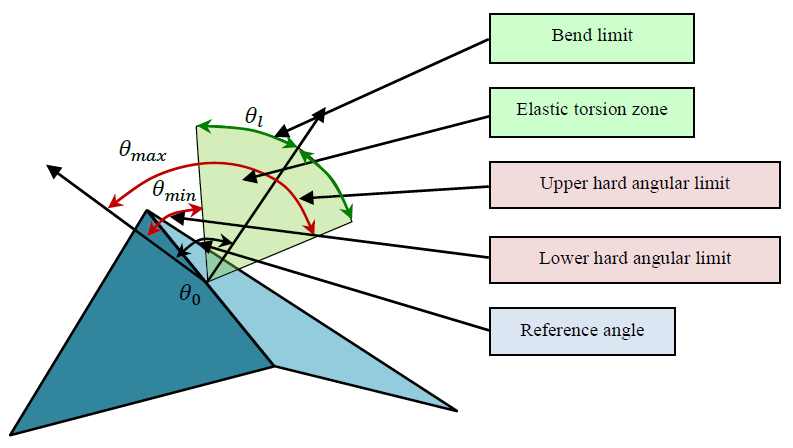

The reference angle (unless using a flat angle model) is computed directly from the reference pose normals and is the angular state the crease will try to maintain using the elastic model, parameterized with the bend stiffness and bend viscosity.

The bend limit is an angle describing a cone around the reference angle. Within the symmetric hard angular limits, the edge crease angle can deform elastically.

Setting a bend limit of zero results in a rigid angular constraint rendering the stiffness and viscosity ineffectual.

Crease reference angle and bend limit.

Note

Setting up the bending properties follows very much the same procedure suggested above for setting segment stretching.